Thank you for purchasing our OA6-110 110V Control Board.

A 110V Control Board is specially designed for Aqua-X Irrigation Control System. It features 6 individual 110V

outputs for the pump control in the Aqua-X Control System. Water pumps are the basic component in automatic flow

control in the irrigation system.

With the use of 110V Control Board(s), the Aqua-X Irrigation Control System could manage up to 30 individually

controlled 110V outputs (used to control water pumps) for multiple watering plans (by schedule or by recycle). With

the massive control outputs, user could manage water delivery schedules easily for multiple nutrients, multiple

rooms and multiple zones.

If you have any questions, please contact us:

Overview

TrolMaster ( Xiamen ) Electronics Co.,Ltd.

2/F, Building A, No.600 West Dongren 2nd Road, Jimei District, Xiamen, China

Features

Operation Instructions

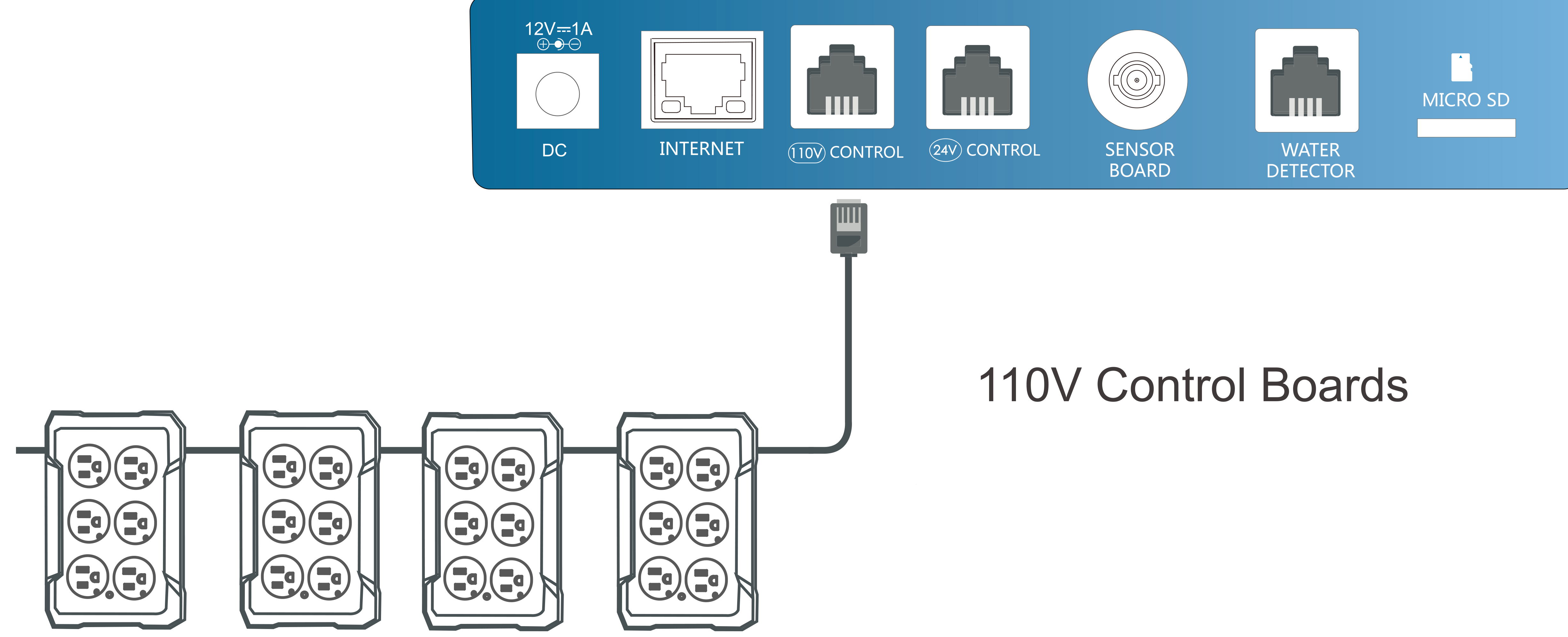

1. Connection to Aqua-X

Use a RJ12 Cable to connect the first 110V Control Board to the Aqua-X Controller. Plug the RJ12

cable connector into the 110V CONTROL port on the bottom of the Aqua-X Controller. Then plug the opposite RJ12

cable connector into the RJ12 cable socket on the either side of the first 110V Control Board.

Use another RJ12 cable to connect the second 110V Control Board. Plug the RJ12 cable connector into the RJ12 cable

socket on the opposite side of the first 110V Control Board. Then plug the opposite RJ12 cable connector into the

RJ12 cable socket on the either side of the second 110V Control Board.

Other 110V Control Boards can be connected in series as above processes. However, the total connection number

should not exceed 5 if the 110V Control Boards were used alone.

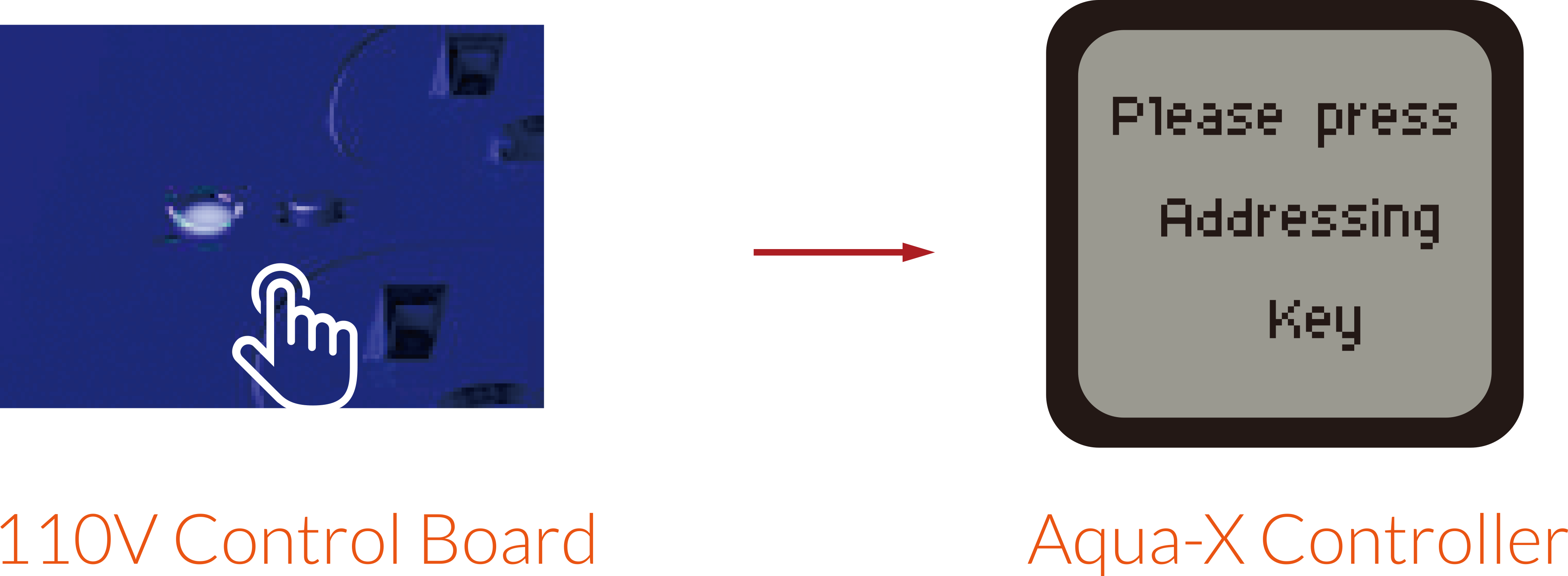

2. Address Assignment

When a 110V Control Board has been successfully connected the the Aqua-X Controller and powered

on, the LED indicator on the Control Board will keep flashing which means that the Control Board has not yet been

assigned to the Aqua-X Controller.

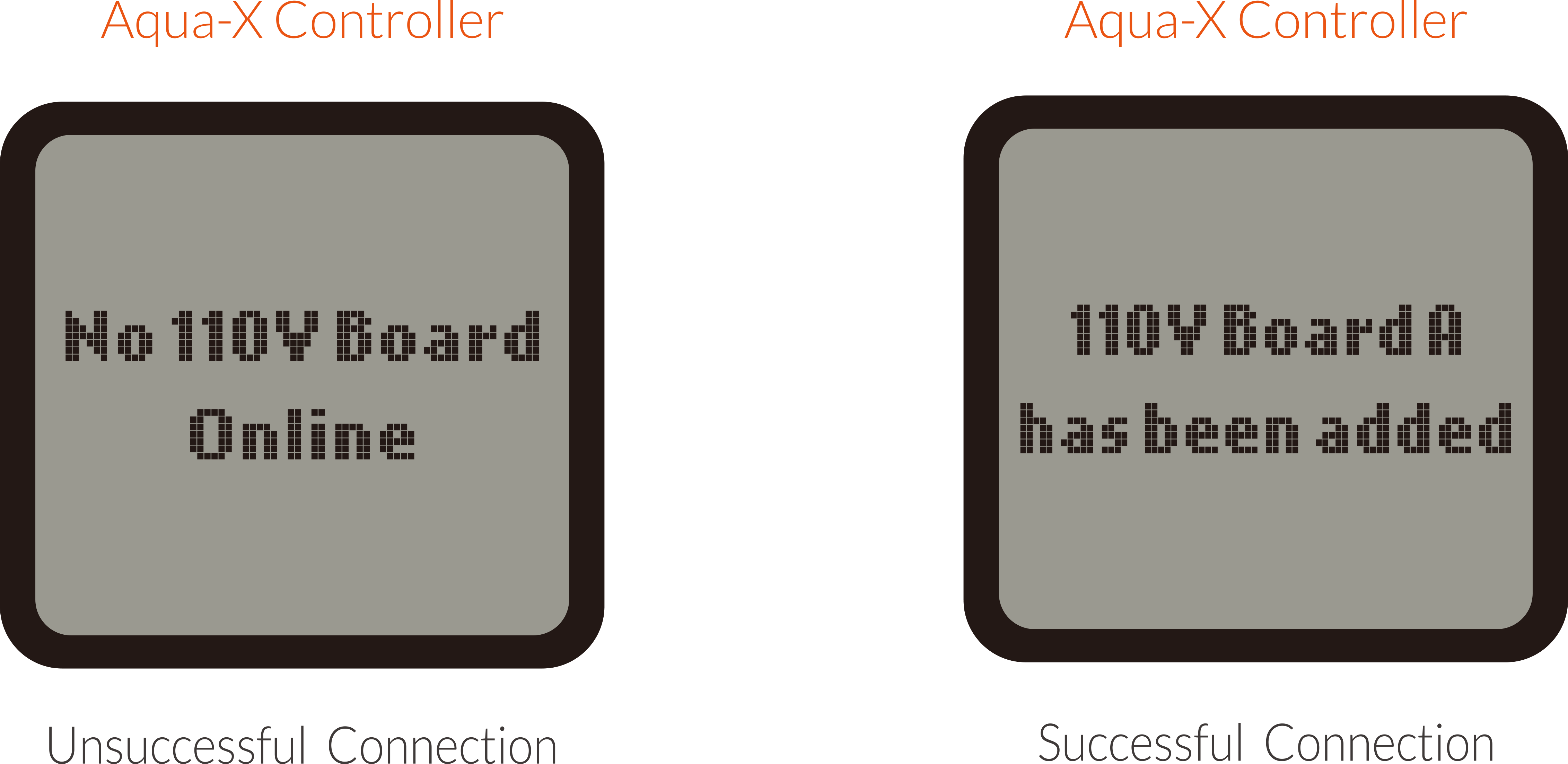

When the RJ12 cable is not correctly connected to the specific 110V CONTROL port or the 110V

Control Board is not connected to the power supply or the 110V Control Board has not yet been assigned to the

Aqua-X Controller, the LCD screen of the Aqua-X Controller will show “No 110V Board Online” on the setting page.

Please make sure the RJ12 cable is correctly connected and power on the 110V Control Board. After power-on, the LED

power indicator will keep flashing every second. Then press the ADDRESSING button on the 110V Control Board, the

LCD screen of the Aqua-X Controller will display “110V Board A has been added”. The first connected Control Board

will be marked as “A”, and the second one marked as “B”, the third one as “C”, and so on.

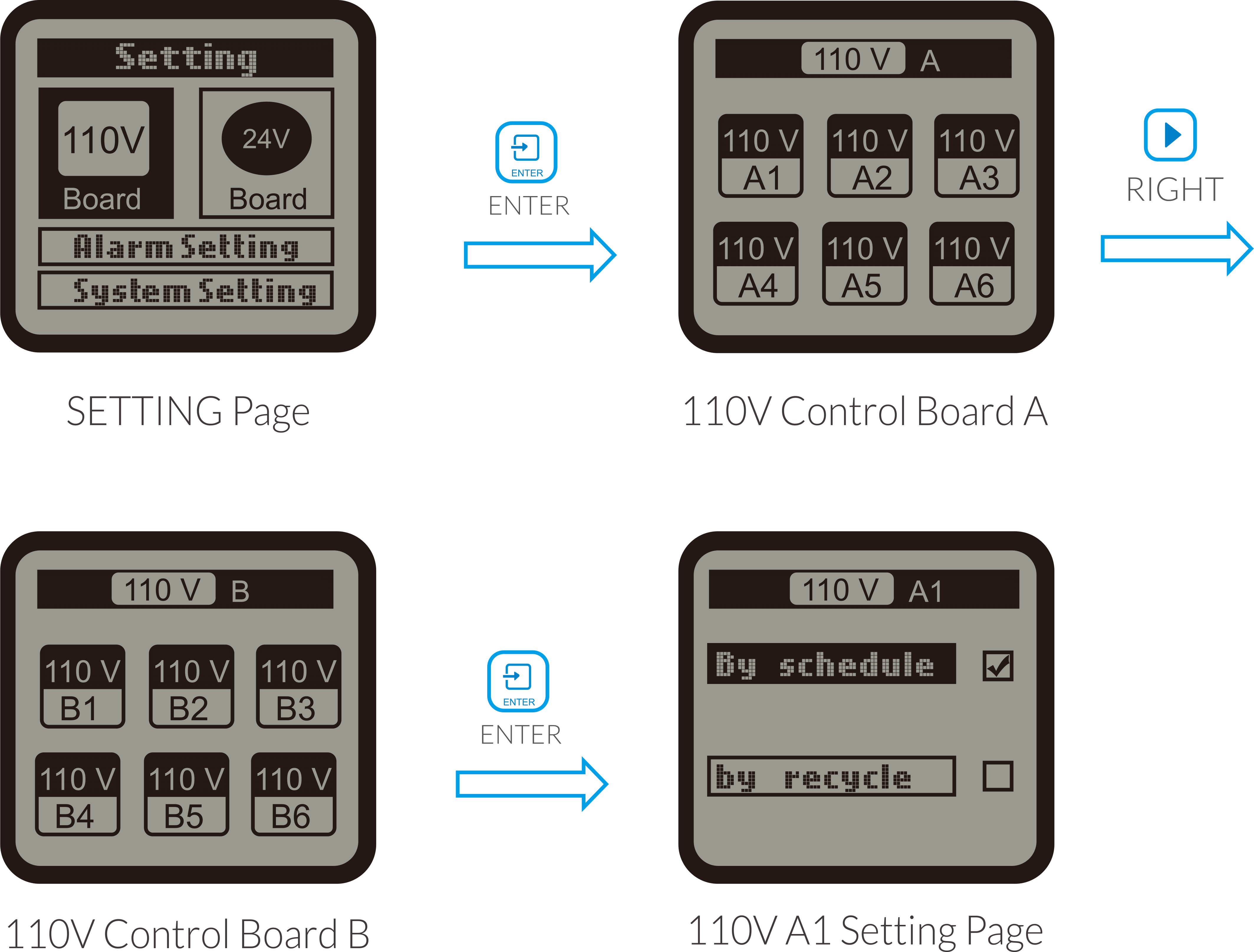

3. 110V Control Board Setting

On the SETTING page, press the ENTER button to enter the 110V Control Board list page. The connected Control

Board(s) will be shown page to page. User can press RIGHT button to select the 110V Control Board (A, B, C…) for

the setting change.

When the Control Board is selected, press ENTER button and the 1st output will be highlighted and blinking. Press

LEFT, RIGHT, UP or DOWN button to select the output such as 110V A1. Press ENTER button to confirm and enter the

SETTING page of that output.

On the SETTING page of selected output such as 110V A1, press ENTER button and the tick icon on

the “By schedule” will be highlighted and blinking. You can also press DOWN button to select “By recycle”. Press

the ENTER button to confirm and save the setting.

a) By Schedule:

Once the "By schedule" setting is selected, user can press ENTER button to activate the setting

for the 1 line of total 12 lines of schedule.The Hour of "On at" time will be highlighted and blinking, which means

that it's ready for change. User can press UP or DOWN button to change the HOUR. Press ENTER button and the MINUTE

of "On at" will be highlighted and blinking, user press UP or DOWN button to change the minute. Press ENTER button

and the SECOND will be highlighted and blinking, user can press UP or DOWN button to change the second. Press ENTER

button and the tick symbol will be highlighted and blinking. Finally, press ENTER button to confirm and save the

changes and the LCD screen will display "Setting saved".

Similarly, user can change the "On at" & "Time" for other schedule ( up to 12 lines) as above processes.

b. By recycle

Once the "By recycle" setting is selected, user can press UP or DOWN button to select " Start",

"On time", "Off time" & "Times" for change. Press ENTER button to activate the setting. For example, when "Start"

selected, press "ENTER" button and the HOUR will be highlighted and blinking, user can press UP or DOWN button to

change the hour. Press ENTER button and the MINUTE will be highlighted and blinking, press UP or DOWN button to

change the minute. Finally, press ENTER button to confirm and save the change and the LCD screen will display "

Setting saved"

Similarly, user can change the "On time", " Off time" and "Times" accordingly.

4. SPECIFICATIONS

5. GENERAL INFORMATION

a). Please use TrolMaster’s components for better performance

b). In the case of defects of the Control Board, the Control Board will either be replaced or

required using new

or reconditioned products or parts by TrolMaster within three-year warranty from the original date of purchase. For

service, return the Control Board in good packaging to our agent with the original sale receipt.

c). Non-professionals DO NOT open the cabinet to prevent electric shock or damage to the Control

Board.

WARNING : DO NOT allow the Control Board to be exposed to

water or excessive heat. DO NOT open or attempt to

repair or disassemble the Control Board, as there are no user-serviceable parts inside. Opening the controller will

void the warranty.

WARNING : DO NOT allow the Control Board to be exposed to

water or excessive heat. DO NOT open or attempt to

repair or disassemble the Control Board, as there are no user-serviceable parts inside. Opening the controller will

void the warranty.

1. If the surface of Control Board is dirty, wipe it with a dry towel.

2. The Control Board is designed for indoor use only, it should be operated under natural ventilation conditions.

3. For safety, it is necessary to connect the ground wire. If a short circuit did occur, the current would

flow through the ground wire, causing a blown fuse or tripped circuit breaker.

4. The Control Board should be positioned in a place that it’s easily to be pull out when a fault occurs.